Standard Deviation: The Hidden Metric Behind Operational Control

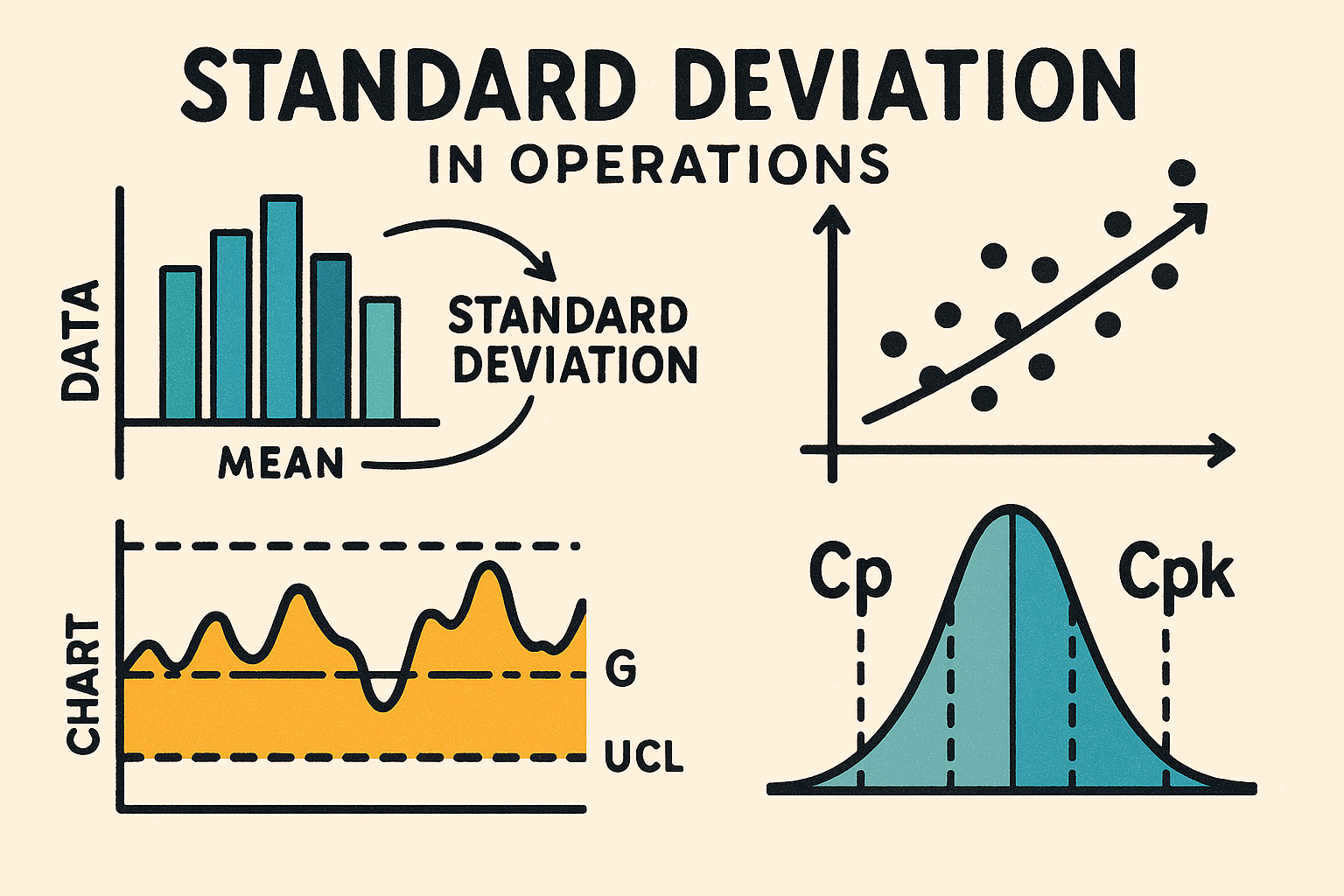

The Magic of Standard Deviation

A car can sink in an average of 2 inches of water...

That line from a quality manager stuck with me. It's a reminder that averages can be dangerously misleading. What really matters is how spread out the data is - and that's where standard deviation comes in.

For the past 10 years, I've used standard deviation across operations - supplier performance, process control, shipment trends, demand forecasting. And here's what I've learned: you can't control what you don't understand, and you can't understand a process without knowing its variation.

Why It Matters

Standard deviation tells you how consistent your data is. In operations, that means:

- Is your supplier reliable or just lucky?

- Is your process stable or chaotic?

- Can you trust your forecast or brace for surprises?

Before you improve a process, you need to know if it's under control. And control starts with understanding variation.

Beyond the Numbers

Metrics like Cp and Cpk are built on standard deviation - but they're just the tip of the iceberg. The real power lies in using deviation to:

- Spot instability before it becomes a failure.

- Make decisions based on confidence, not hope.

- Ship not just products, but capable processes.

The Bottom Line

Standard deviation isn't just a statistic. It's a daily operational compass. It helps you see beyond the average, into the heart of your process.

And once you see it, you can control it.